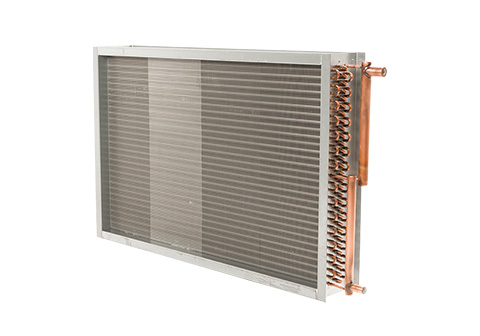

Condenser Coil

We offer a range of services covering HVAC, Plumbing, Process, Clean rooms, Labs, AMC (Annual Maintenance Contract), Electrical, and Piping (SS & MS) industries, along with other specialized solutions.

Condenser coils are used to reject heat from an air-conditioning or refrigeration system. Sometimes they are used with the intention to heat air streams. They are one of the four main components in the refrigeration or air-conditioning cycle. Refrigerant enters as a superheated gas and condenses in the coil tubes as the air is heated. The refrigerant leaves the coil as a liquid.

Elementary Surface:

Round seamless copper tubes are expanded using hydropneumatics water expansion system into the fin collars of the secondary surface. The hydropneumatics water expansion system provides a permanent metal-to-metal bond for efficient heat transfer. Tubes are staggered in the direction of airflow.

Secondary Surface:

Corrugated aluminum or copper plate type fin that is die-formed. Fin collars are full-drawn to provide accurate control of fin spacing and maximum contact with tubes.

Headers:

Seamless copper with die-formed holes that provide a parallel surface to the coil tube for strong brazing joints.

Connections:

Copper outside diameter (O.D.) Sweat with standard arrangement for one compressor circuit. FACE SPLIT circuiting available for two or more compressors.

Casing:

Casing is die-formed with 1½” flanges to permit easy stacking and mounting. Intermediate tube supports are supplied on coils over 44” fin length with an additional support every 42”.

Testing and Performance:

All coil assemblies are leak tested under water with nitrogen at 400 PSIG.

Circuiting:

Coil circuiting options include full face (std.) and horizontal (face) split.