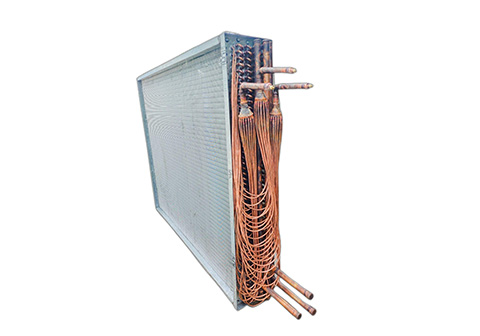

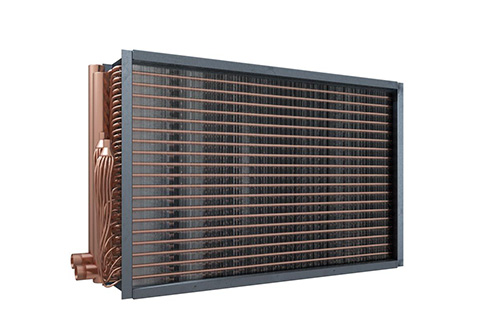

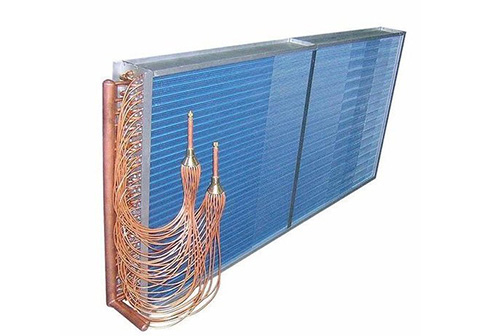

Direct Expansion Coil

We offer a range of services covering HVAC, Plumbing, Process, Clean rooms, Labs, AMC (Annual Maintenance Contract), Electrical, and Piping (SS & MS) industries, along with other specialized solutions.

Elementary Surface:

Round seamless copper tubes are expanded using hydropneumatics water expansion system into the fin collars of the secondary surface. The hydropneumatics water expansion system provides a permanent metal-to-metal bond for efficient heat transfer. Tubes are staggered in the direction of airflow.

Secondary Surface:

Corrugated aluminum or copper plate type fin that is die-formed. Fin collars are full-drawn to provide accurate control of fin spacing and maximum contact with tubes.

Headers:

Seamless copper with die-formed holes that provide a parallel surface to the coil tube for strong brazing joints.

Connections:

Interchangeable nozzle type refrigerant distributors are brass and suction connections are copper sweat. Standard coil has one distributor for one compressor circuit. An INTERTWINED coil has two distributors that provide full face control using two compressor circuits. A FACE SPLIT coil has two or more distributors for multiple compressor circuits.

Casing:

Casing is die-formed with 1½” flanges to permit easy stacking and mounting. Intermediate tube supports are supplied on coils over 44” fin length with an additional support every 42”.

Testing and Performance:

All coil assemblies are leak tested under water with nitrogen at 315 PSIG

Circuiting:

Coil circuiting options include full face (std.), intertwined, horizontal (face) split, and face split / intertwined.